Shut In Tool

Well Surveillance & Monitoring

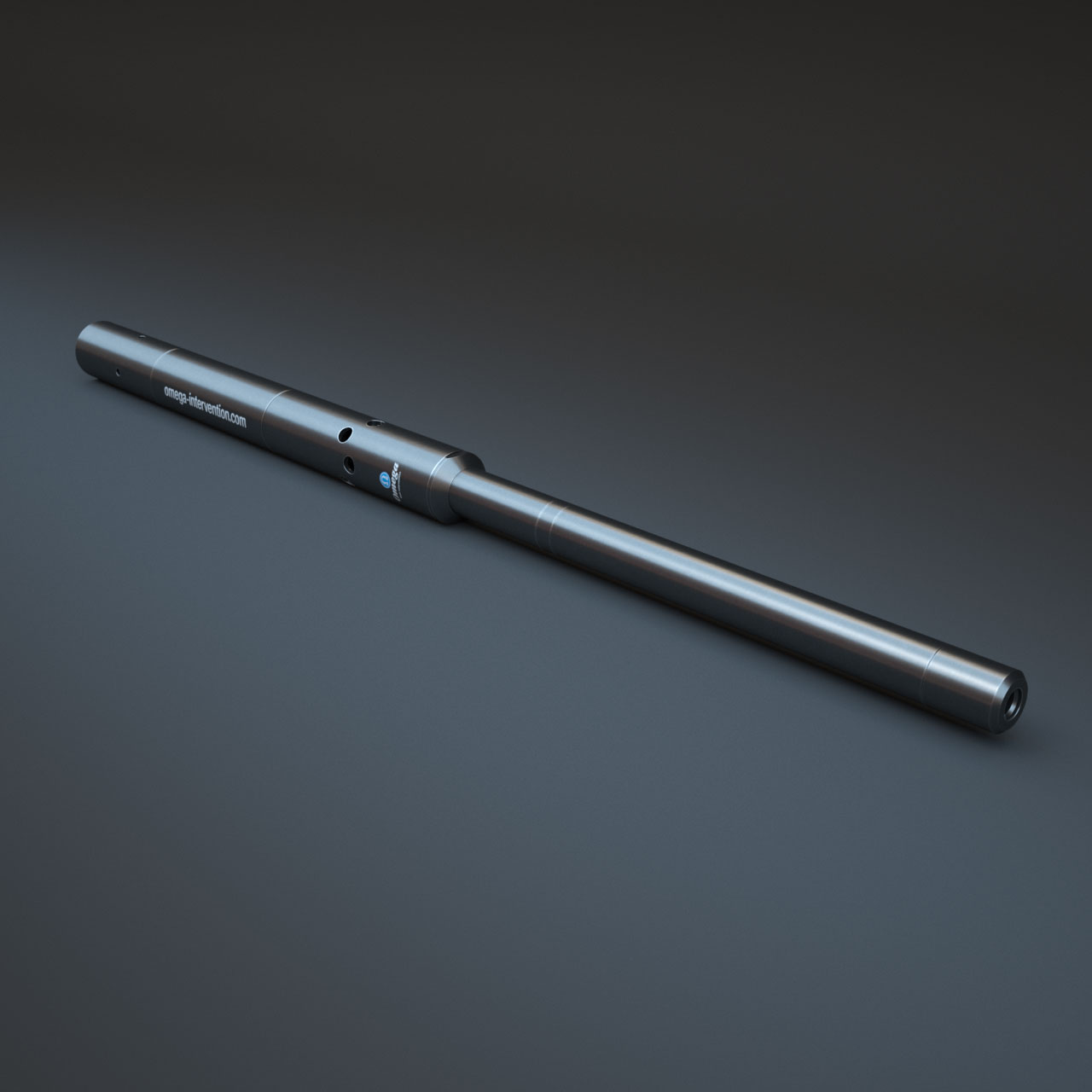

Shut In Tool

The Omega Shut In Tool is a single shot battery driven device which has been designed for basic well testing situations when a flowing well is shut in downhole and the resulting pressure build up is monitored by memory gauges. The S.I.T. is screwed on to the bottom of a lock mandrel and equalising assembly and is run and set into a nipple in the normal way.

Following retrieval of the slickline string, the well is flowed through the flow ports in the S.I.T., through the cylinder cross-over, through the lock and up to surface. The cylinder cross-over is always sized to the lock so that the minimum restriction will always be the lock.

The timer is programmed at surface prior to running by setting two rotary switches to the required time delay. Following completion of the delay, the clock powers a motor/ gearhead assembly which changes the position of a valve pin. The valve pin previously isolated well pressure from a closing piston. Movement of the valve pin allows well pressure to act on this piston providing an upwards force which is transferred to a closing plug. The closing plug features three o-rings which are protected by a sleeve. The closing plug is pushed into the bore which the well is flowing through shutting off the flow.

Once time has been allowed for the well pressure to fully build up, the lock, equalising assembly, S.I.T. and gauge string may be retrieved in the normal way. The equalising assembly is opened and once the well pressure has equalised, the tools may be removed from the nipple.

FEATURES

- Built in equalising assembly.

- Large flow area through tool.

- Field proven electronics from the Omega Hydrostatic Setting Tool.

- Protected seals on closing piston.

- Sized to fit any lock mandrel or retrievable bridge plug.

APPLICATIONS

- Provides pressure build up monitoring.

- Deployed below lock or bridge plug.

BENEFITS

- Reduces well bore storage effects during pressure surveys.

- Eliminates pressure data inaccuracies caused by gas expansion.

- Eliminates pressure data inaccuracies caused by phase segregation.