Cement Dump Bailer

Well Abandonment

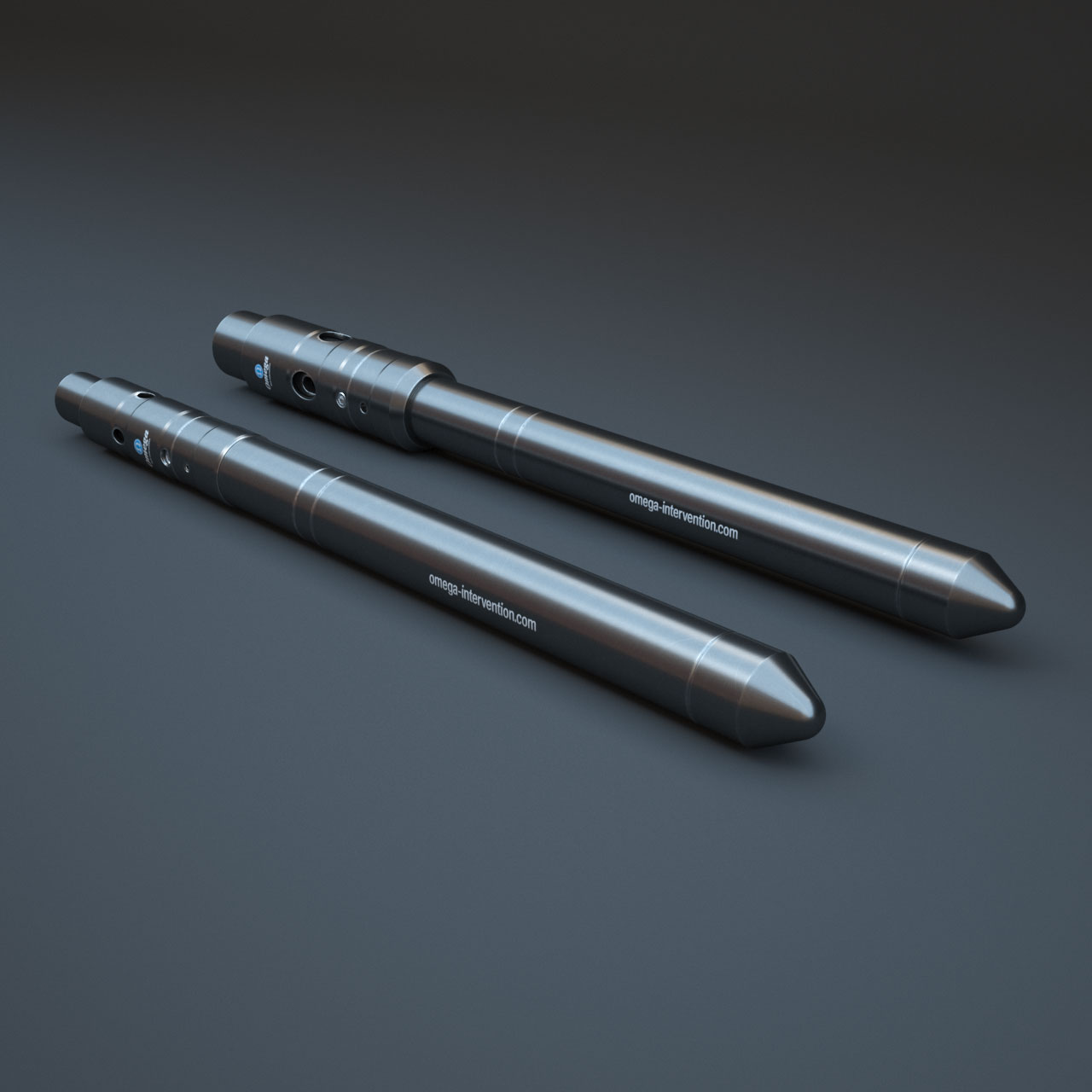

Cement Dump Bailer

The Omega Cement Dump Bailer is a single shot device which has been designed to accurately deliver large volumes of cement/acid/chemicals/sand or proppant to a downhole location via slickline or braided line.

Due to its modular design, the dump bailer actuator can be made up to any number or size of tube sections. The number and diameter of these tubes is dictated by the available rig up height, minimum well bore restriction and the final overall tool string weight.

The electronic timer is pre programmed at surface prior to running by the setting of two rotary switches, these select the appropriate delay time for the dump bailer downhole activation. Once the dump bailer is filled and prepared for deployment, the time delay period is started by simply threading the nose cone fully in to the actuator body of the tool.

Following expiry of the pre-programmed time delay, well pressure floods a hydrostatic chamber in the actuator, this provides the upward motion required to fully open the valve sleeve. The previously contained cement/acid/chemical/sand or proppant is now free to drain from the tube sections via the large flow ports on the actuator at the desired downhole location.

FEATURES

- High volume capacity, modular filler tubes.

- Field proven Omega electronic timer.

- System rated up to 185°C & 15,000psi.

- Variable delay time.

- No tagging or jarring action required to actuate.

- Top & bottom filling options.

APPLICATIONS

- Slickline deployment of cement/sand/proppant above barrier plugs.

- Well abandonments.

- Scale removal from safety valves/plugs/Xmas tree using acid/chemicals.

- Hydrate removal.

- Deployment of tracer fluids.

BENEFITS

- Deployed via slickline, reducing E-line requirements.

- Accurate deployment of sand/proppant/cement/acid/Methanol.

- No pyrotechnics required to operate tool.

- Modular design facilitates access in restricted height deployment.