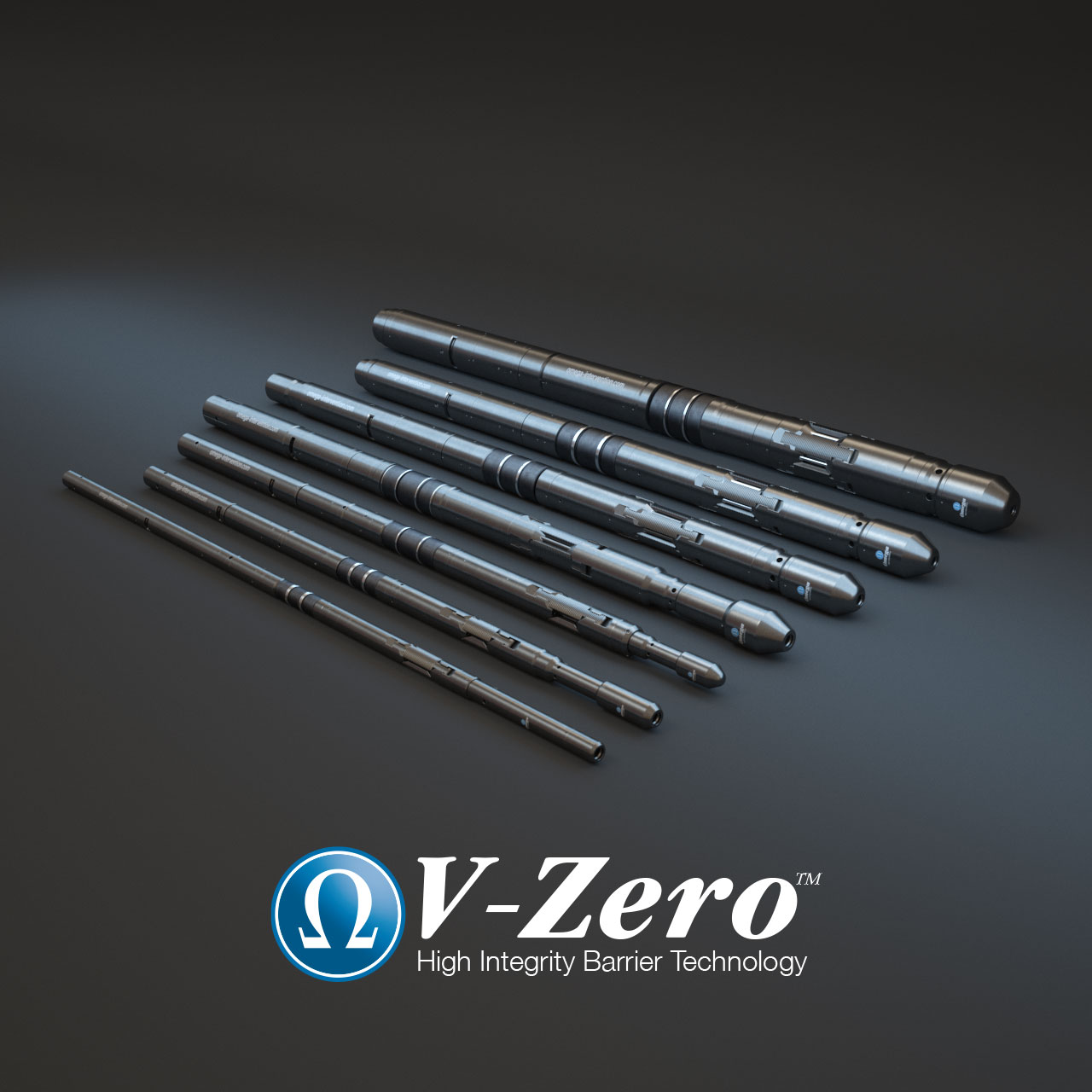

Retrievable Bridge Plugs

Well Isolation

Retrievable Bridge Plugs

The Omega Retrievable Bridge Plug is a high performance monobore plugging device which can be set at any required depth in the tubing or casing. The plug is deployed, equalised and retrieved using conventional well intervention methods.

Deployment is achieved in one run, as is the subsequent equalisation and retrieval of the plug. This enables a reduction in both well intervention risk and subsequent operational cost.

The Retrievable Bridge Plug features bi-directional slips which anchor the plug to the well casing prior to pack-off of the element to form the pressure seal, making it ideal for cross flow applications. The large ‘through bore’ design ensures full equalisation occurs prior to retrieval. This also means that secondary devices can be installed onto the lower section of the plug such as Omega’s remotely activated equalising valves.

Omega API 11D1 V0 qualifies the V-Zero™ Retrievable Bridge Plug range to 5,000 psi @ 150º C – 4 º C.

V3 qualified Gemini Plugs are available on request. Contact your Omega representative for more specific and updated testing information.

FEATURES

- Medium expansion slips and element.

- Highly debris tolerant due to innovative equalising/retrieval design.

- Retrieval mechanism enables successful retrieval in one intervention.

- Bi-Directional mechanical slips.

- Large slip footprint maximises slip/casing contact area.

- Overall length minimized for restricted access deployment.

- Set using conventional intervention setting tools, such as Omega’s Hydrostatic Setting Tool (HST).

- Option to install a Lower Junk Catcher Extension in high debris environments.

APPLICATIONS

- Well barrier during well maintenance and workover’s.

- Zonal isolation, water shut off or treatment.

- Pre-installation in completion tail-pipe for packer setting.

- Contingency packer setting.

- Testing of production tubing(s).

BENEFITS

- Increased operational performance due to setting and releasing mechanisms.

- No specialized retrieval tool required, standard GS pulling tool used to equalise and retrieve.

- Optimised slip design reduces stress loading on tubulars.

- Controlled setting action, further enhanced with the Omega HST.

- Through bore design provides secondary functionality and increased debris tolerance.