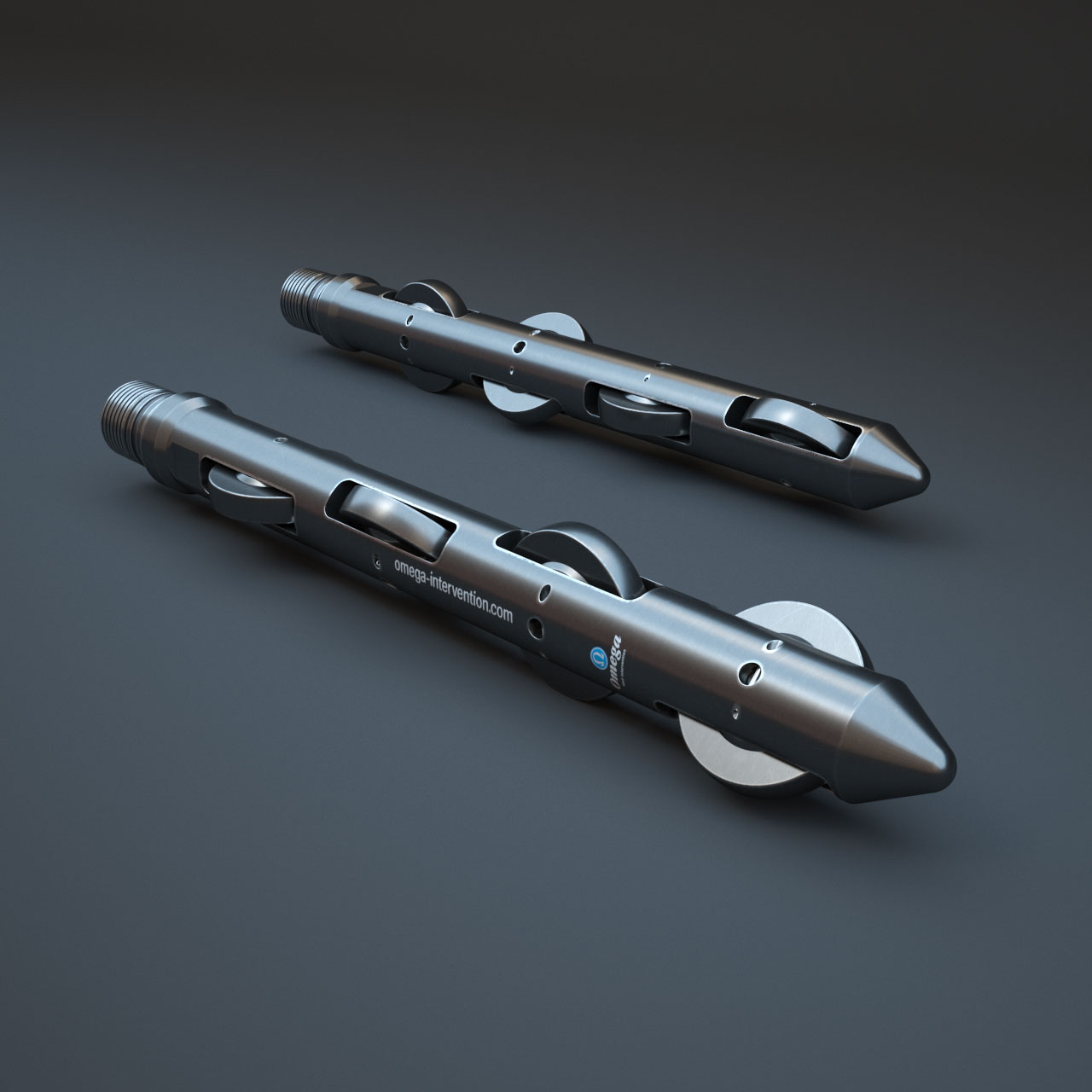

Perforating Roller Bull Nose

Wireline Products

Perforating Roller Bull Nose

The Omega Perforating Roller Bull Nose is a friction reduction device for use at the bottom of a perforating gun assembly. Its primary function is to centralise & support the perforating assembly while at the same time guiding it through the well jewellery. The 360 degree wheel coverage design combined with the unique triple bearing system helps minimise tool drag and allows free movement at the bottom of the perforating assembly.

Used in conjunction with the Omega High Deviation Rollers, the perforating roller bull nose is an extremely effective friction reduction solution and as a result significantly reduced run in and pick up weights are achieved. The Omega Roller Sub design is proving to be the most reliable, effective system on the market today and we welcome the opportunity to demonstrate that fact.

FEATURES

- Interchangeable hardened wheels.

- Thrust & angular bearings fitted throughout.

- Extremely robust design.

- 360° Wheel coverage.

APPLICATIONS

- Friction reduction in deviated well bores.

- Centralisation of downhole devices.

- Electric line perforating.

- Tubing conveyed perforating.

BENEFITS

- Enables use of wireline in high deviation wells.

- Provides “Tool Lift”.

- Highly debris tolerant.

- Greatly reduces tool string friction, allowing target depth achievement.

- Impossible for wheels to disengage from tubing I.D.