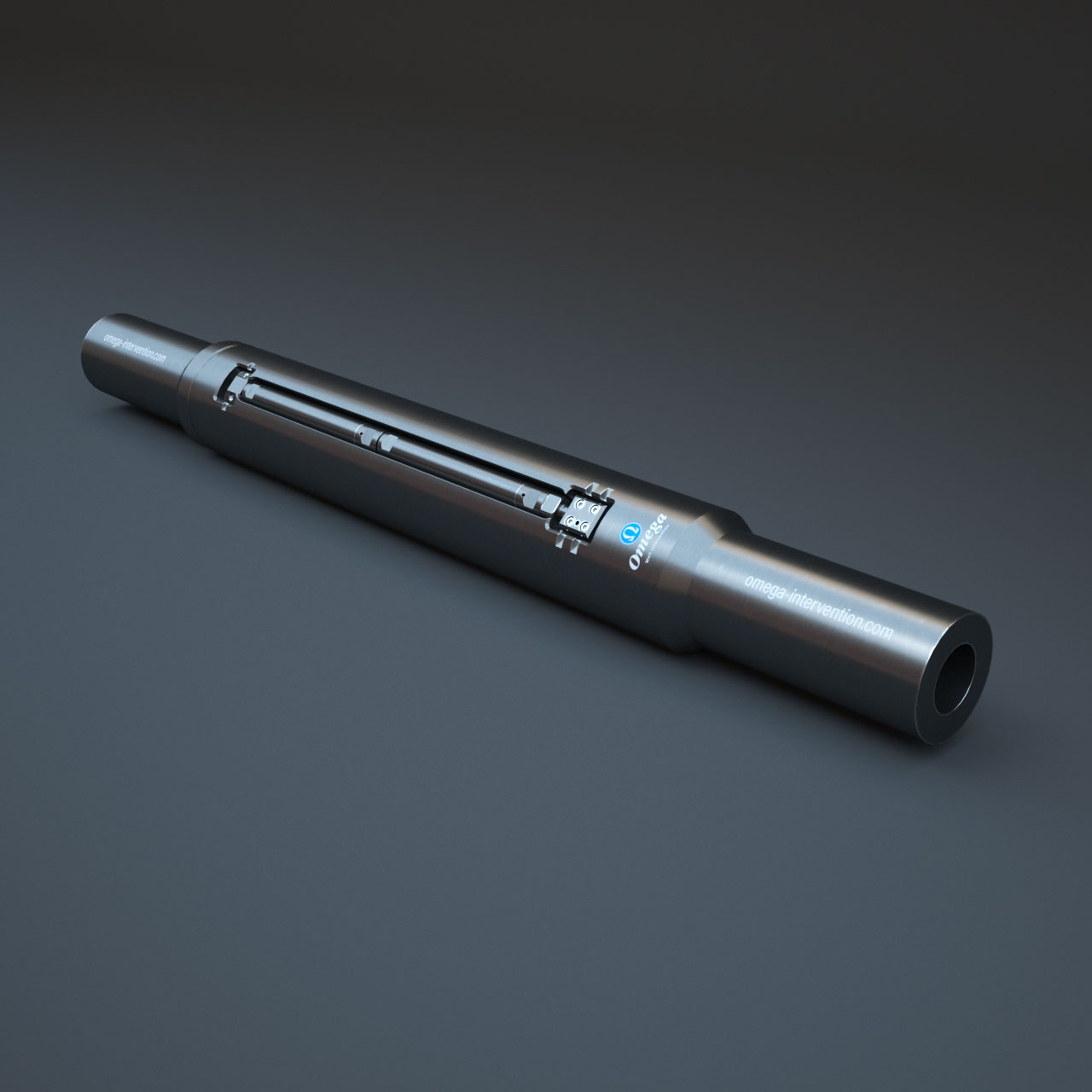

Internal - External Gauge Carrier

Well Surveillance & Monitoring

Internal - External Gauge Carrier

The Omega Internal / External Gauge Carrier is designed as a platform for data acquisition. The Internal / External Gauge Carrier provides one pocket, which houses two Omega Micro Automatic Gauges and/or accelerometer units. The micro Automatic gauges provide a record of internal drill pipe ID pressure and temperature and well bore pressure and temperature.

When dressed with accelerometer units, stick slip, rotation, well deviation, vibration as well as acceleration /deceleration is measured and stored in memory. Designed to be deployed on drill pipe, the carrier is ideally suited for drilling, liner cementation, and expandable applications. The Omega Internal / External Gauge Carrier requires no input from the operator. Once made up to the drill pipe the micro automatic gauges will automatically start to record data once the pre-programmed temperature and pressure thresholds are exceeded and switch off automatically, below the thresholds when retrieved to surface.

The Omega Micro Automatic Gauge and accelerometer unit have their own built in real time clock allowing any number of gauges to be synchronised to each other and a surface reference point.

FEATURES

- Standard field proven memory gauges.

- Gauges start recording automatically.

- Temperature compensation.

- No Specialised personnel required.

- Standard Omega software compatible with windows.

- No dangerous goods certification required.

APPLICATIONS

- Monitoring gravel pack operations.

- Drill stem testing DST

- Monitoring liner running strings during cementing operations.

BENEFITS

- The ability to record actual data directly above the drill bit, expansion device or during cementing operations.

- Data may be downloaded and reviewed at the rig site.

- Compact dimensions do not impact on the BHA design.

- Ideally suited for surface testing of new equipment.