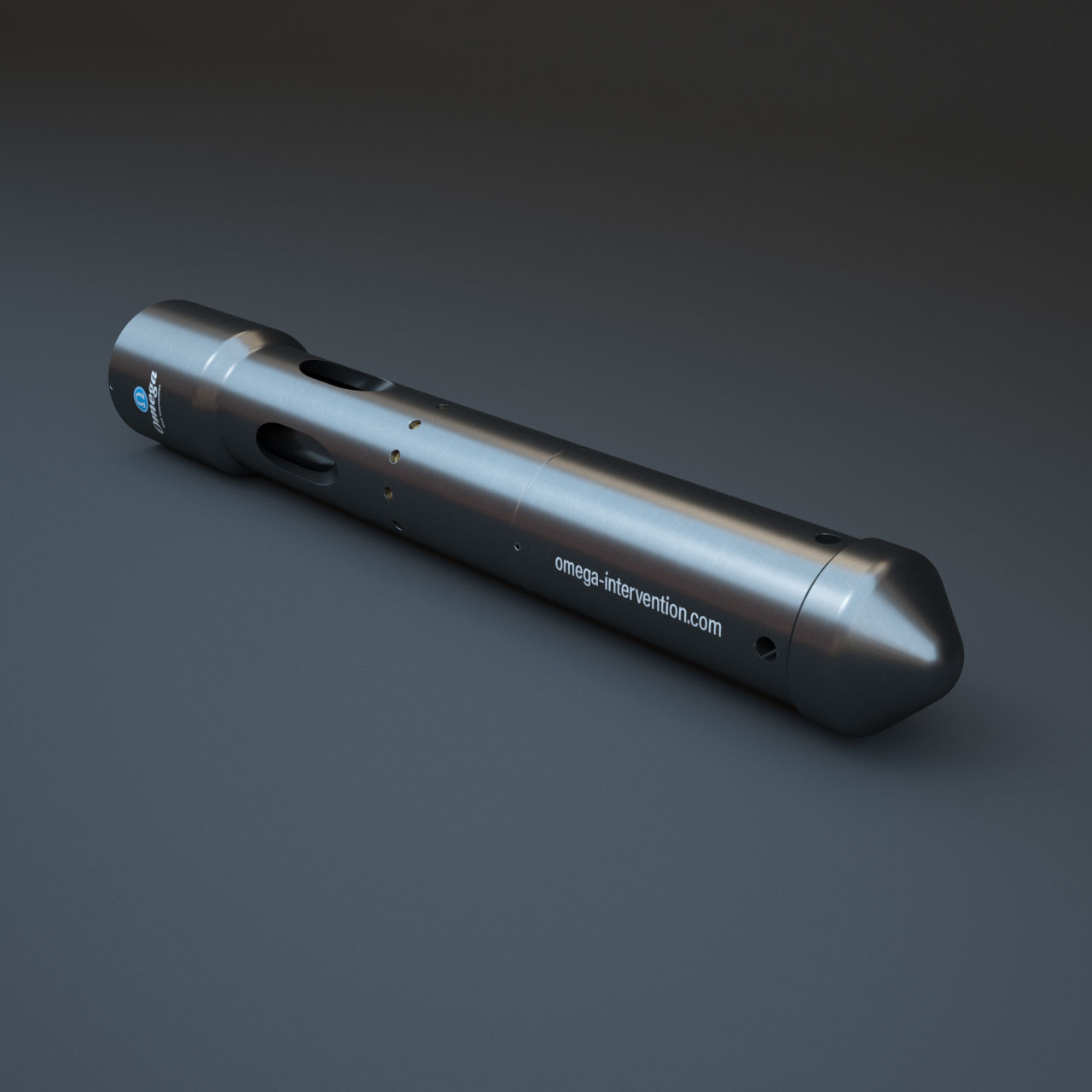

Pump Open Sub

Well Isolation

Pump Open Sub

The Omega Pump Open Sub is designed to provide an equalising facility, prior to the retrieval of a bridge or blanking plug. Alternatively, by attaching the pump open sub to any packer or lock, it provides a positive barrier between the tubing and the well bore fluid below.

The pump open sub is run in hole in the closed position. Pressure can be applied to the tubing to pressure test and set completion equipment above the tool.

The pump open sub is opened to allow equalisation prior to the retrieval of the plug or lock, or to allow production well fluid to flow up into the tubing above. This is achieved in one of two ways. Pressure can be applied to the tubing which results in a load being applied to the shear screws, once a predetermined load is reached the screws shear, allowing the plunger to drop down inside the larger bore, a snap ring on the plunger then engages in a recess within the lower bore positively locking the tool open.

The plunger can also be mechanically pushed off seat using a prong. Sufficient load needs to be transferred through the plunger into the shear screws, the plunger is then pushed to the bottom of the tool and locked in position.

FEATURES

- Qualified in accordance with ISO14310 VO testing requirements.

- Equalized via mechanical impact or by applying a predetermined pressure from above.

- Fully adjustable activation pressure.

- Once equalised the device is retained in the open position.

- All shear screws are retained within the tool.

APPLICATIONS

- Temporary well suspension.

- Completion or workover operations.

- Tubing integrity testing.

- Zonal isolation.

- High debris potential applications.

BENEFITS

- Simple maintenance and field redressable.

- Variable actuation pressure.

- Easily adapted to any RBP or flow control lock.