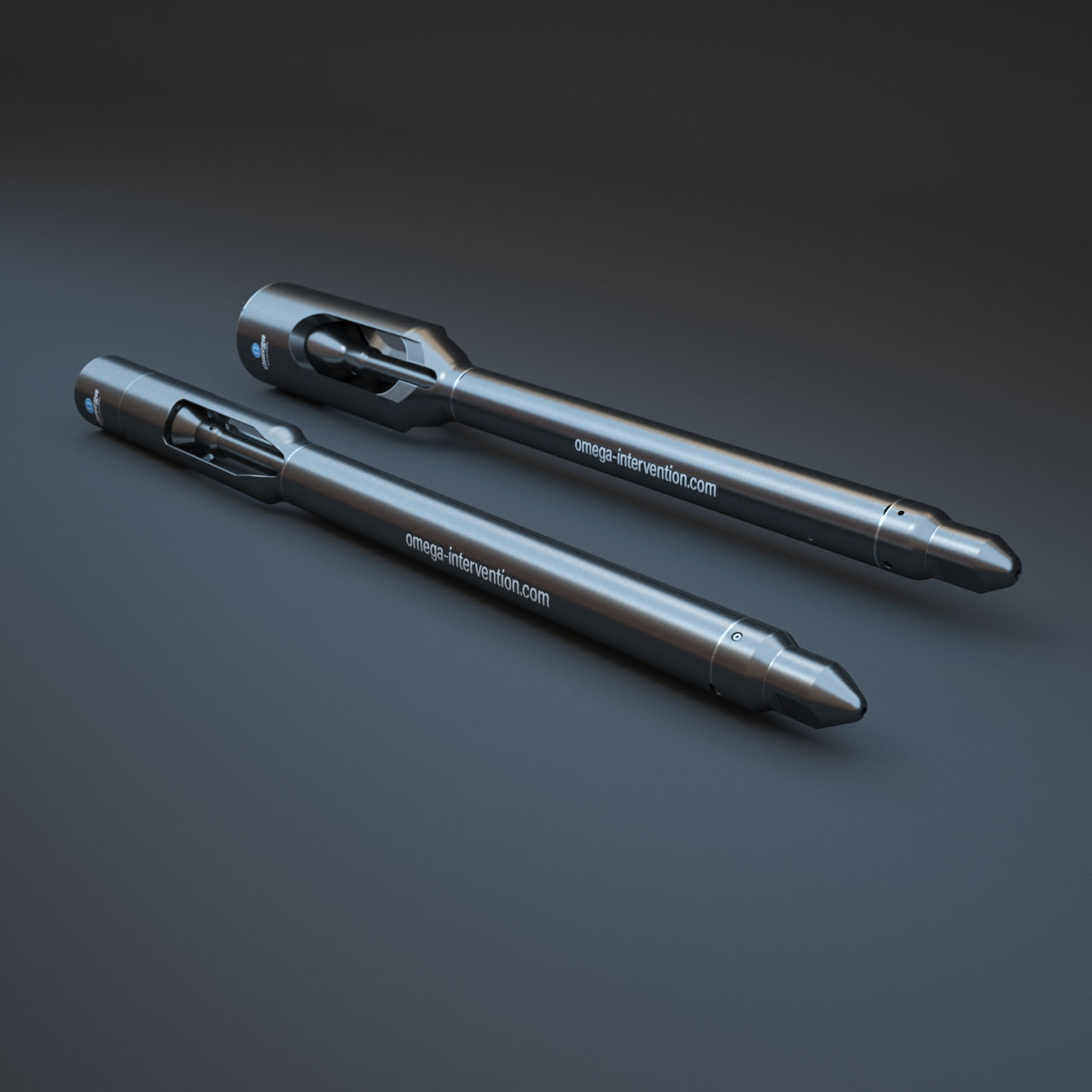

Water Injection Valve

Well Isolation

Water Injection Valve

The Omega Injection Valve is unique within the market place as it incorporates a hydraulic dampening system to prevent any unwanted vibration, which often occurs during the injection process.

The debris tolerant seal face ensures, when closed, that there is always contact between the plunger and the seal ring. The dampening system also allows the valve to ‘close softly’ thus preventing any damage to the seal faces when injection ceases.

The large annular flow ports maximise available flow area through the valve negating the pressure drop concerns of similar type tools.

The injection valve is biased closed and opens when injection fluid is pumped down the tubing. The plunger moves off seat compressing a spring below and allowing the injection fluid to exit the valve via the large flow ports.

When pumping is stopped the spring then forces the plunger back up the ID of the tool to the seal face, preventing any fluid from below the valve flowing back into the tubing above.

FEATURES

- Hydraulic dampening system to prevent unwanted vibration.

- Soft closure feature to extend plunger seal life.

- Debris tolerant seal system.

- Anti-rotation connections.

- Large annular flow ports.

- Metal To Metal Seal increases durability.

APPLICATIONS

- Deep set barrier in injection wells.

- Can be installed below plugging devices.

BENEFITS

- Longer operating life.

- Reduced redress costs.

- Provides high injection rates with low pressure drops.